The oil and chemical industry operates for long periods in high-noise environments. Large rotating machinery, high-speed fluid transportation, and continuous process operations generate intense noise, which not only reduces on-site communication efficiency but also poses long-term risks to worker health and operational safety.

1. Project Requirements

In a large-scale chemical plant project in North Africa, the customer faced complex and harsh operating conditions and put forward clear and practical requirements for the on-site communication system:

-

A relatively quiet communication space in high-noise areas

-

Incoming calls must be clearly perceived in noisy environments

-

Communication equipment must offer industrial-grade reliability and durability

-

The solution must withstand high temperatures, high humidity, dust, and corrosive conditions

-

A mature, stable, and easy-to-deploy solution was required to improve on-site communication efficiency and safety

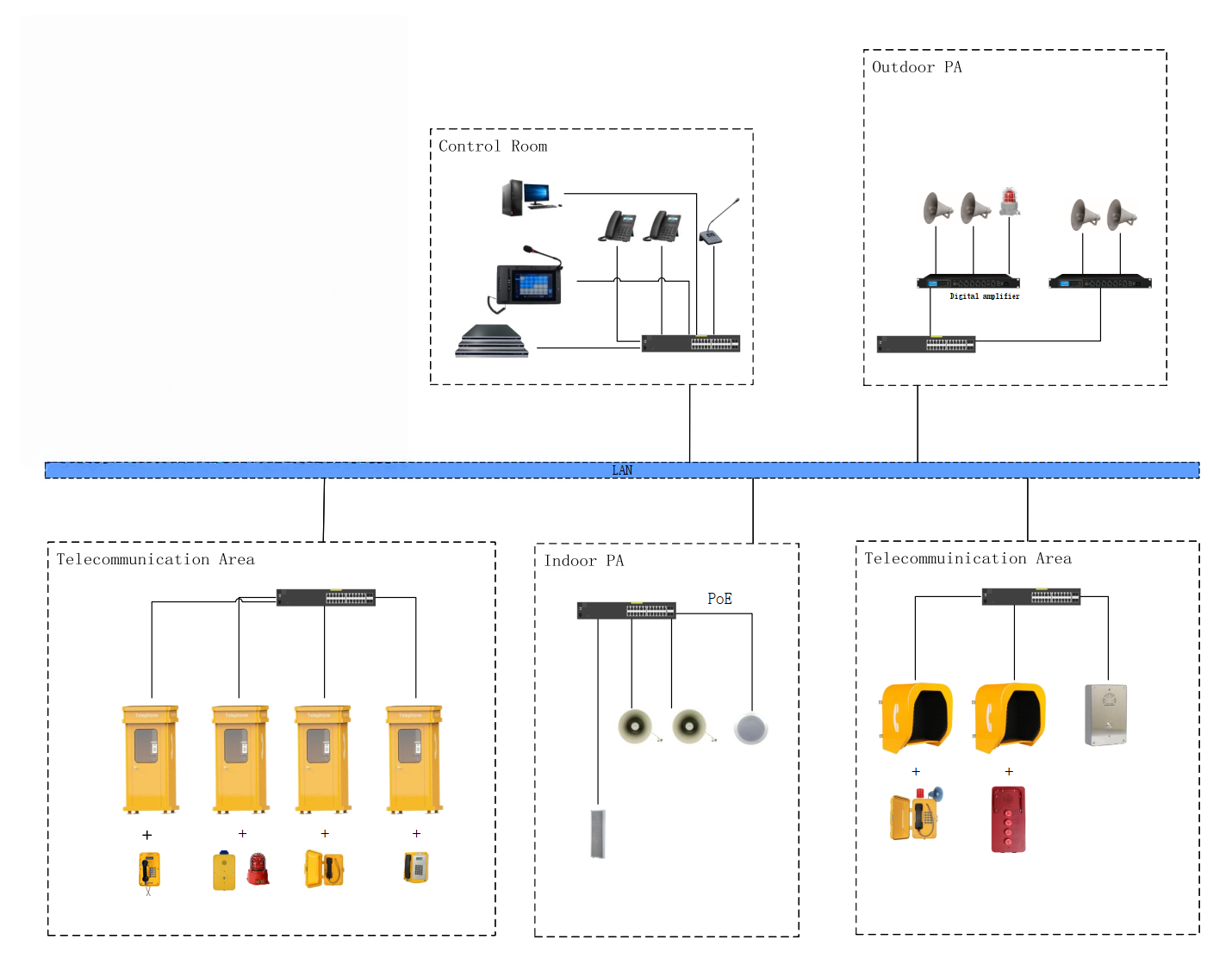

2. Solution

In response to these requirements, J&R Technology delivered an integrated communication solution combining the JR104-SC Industrial Telephone, JR-TH-03A Cold-Rolled Steel Noise-Reduction Booth, and a sound-and-light alarm.

The JR104-SC industrial telephone is installed inside the JR-TH-03A noise-reduction booth, providing operators with a quiet and controlled communication environment. A sound-and-light alarm is installed outside the booth, ensuring that incoming calls are clearly noticed even in extremely noisy conditions, enabling timely response to critical communications.

The JR-TH-03A noise-reduction booth features a welded cold-rolled steel structure, offering excellent sound insulation and weather resistance. An integrated warning light is installed on the top, and dedicated mounting space is reserved inside for communication equipment. The overall design fully meets the basic communication and safety requirements of chemical plant environments.

Following on-site installation, the system has been operating stably, and its noise-reduction performance has been highly recognized by the customer.

3. Key Solution Highlights

- Integrated Noise Reduction and Communication

Combined use of a noise-reduction booth and industrial telephone ensures clear communication in high-noise environments -

Visible and Audible Call Alerts

Sound-and-light alarms enhance incoming call awareness and prevent missed critical information -

Industrial-Grade Structural Design

Cold-rolled steel construction suitable for high-temperature, high-humidity, and corrosive environments -

People-Oriented Design

Provides a relatively quiet and comfortable communication space, reducing noise exposure risks -

One-Stop Deployment

Coordinated equipment design enables easy installation and maintenance, meeting real-world chemical plant needs

4. Further Engagement

At the customer’s invitation, J&R Technology participated in Préventica Casablanca 2025, where we showcased our core products, including industrial telephones, emergency communication systems, and noise-reduction booths. During the event, we engaged in in-depth discussions with industry clients, system integrators, and partners from North Africa and around the world.

Focused on communication challenges in the oil and petrochemical industry, J&R Technology offers customized PA & intercom systems and integrated communication solutions, delivering a true one-stop service platform for industrial communication needs.

For more information, please feel free to contact us.